Precise plastic contract manufacturing

Valukumpu specialises in plastic injection moulding, punching of precise metal components and automised assembly solutions. We have long experience in combining plastic and metal.

We provide contract manufacturing to various industries, such as the telecom, electronics, medical and electrical industries. We also participate in other phases of production from the product design, tool desing as well as process planning. Our services also include high quality tool manufacturing and automation.

Our range of connectors available for the electronics industry can be found here >

Turnover

(EUR million)

Personnel

Experience

(years)

PRODUCTION

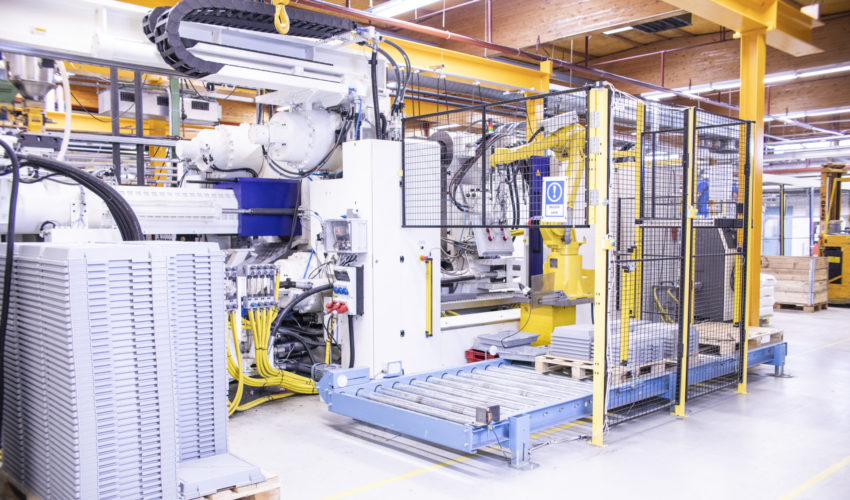

Valukumpu has a 20,000 m² production facility, providing excellent capacity for producing plastic and metal components. We provide ISO 13485 manufacturing of medical devices in controlled production space (ISO class 7). Automated assembly solutions are extensively used in accordance with customer requirements. Our latest production technologies include:

Injection moulding

• Micro-moulding (part weight > 8mg)

• Injection moulding (part weight < 6 kg)

• Multiple component injection moulding (2K/3K)

• Overmoulding, combining plastic and metal

• Liquid silicone rubber moulding LSR

• Gas-assisted injection moulding

• Thermoset injection moulding

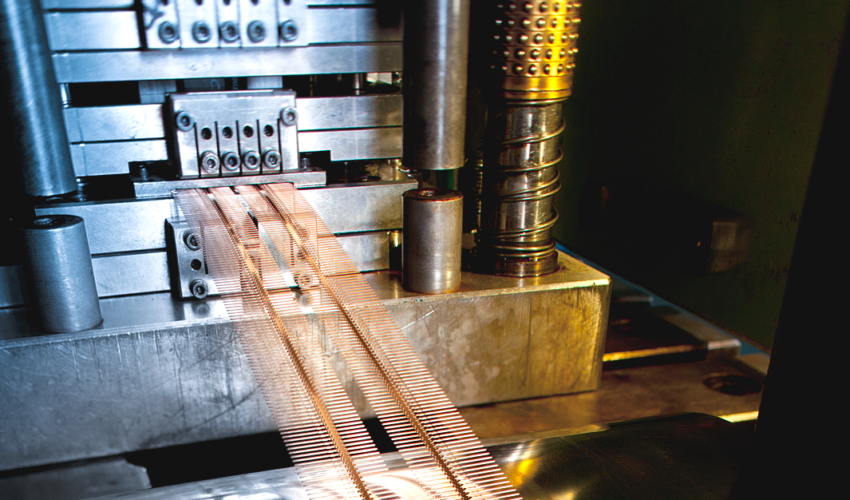

Punching

• Material thickness range: 0.05-6.00 mm

Electroplating

• Plating materials: Ag, Au, Ni, PdNi, Sn

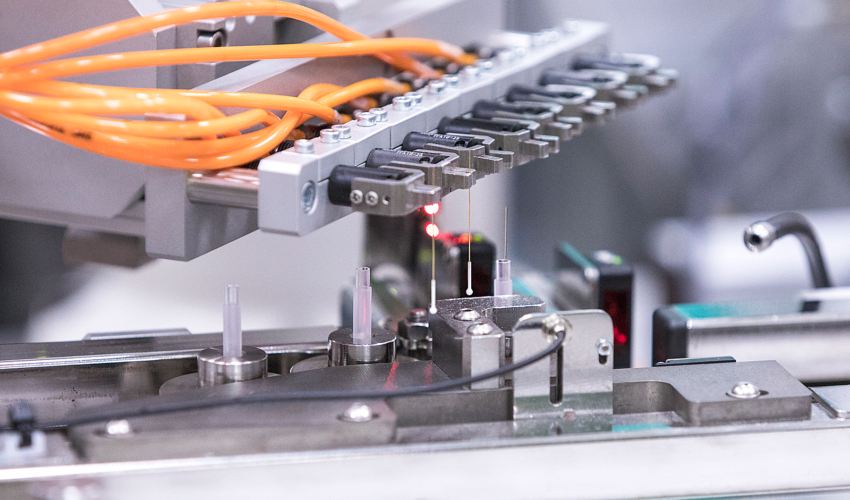

Assembly

• Manual assembly

• Automated assembly solutions

• Assembly of medical devices (To ISO 13485 Standards)